Technologies

Locksmith Operations

Mechanical engineering production inherently includes various locksmith operations, which are an integral part of workpieces and different assemblies. As far as we are concerned, this category of operations includes the cutting, drilling, threading, riveting, pressing, straightening, deburring, grinding, and of course the machining of metallurgical material.

- Cutting of Metallurgical Material:

- Band saw with conveyor

- Straight and oblique cuts

- Maximum profile diameter 320 × 250 mm

- Pressing of PEM elements:

- Pressing force max. 6 t (M2-M12)

- Pressing of PEM elements into thin sheets

- The joint can be stressed with great force even in thin metal sheets

- High accuracy of element mounting

- Press nuts, press studs, press bushings and other types of elements

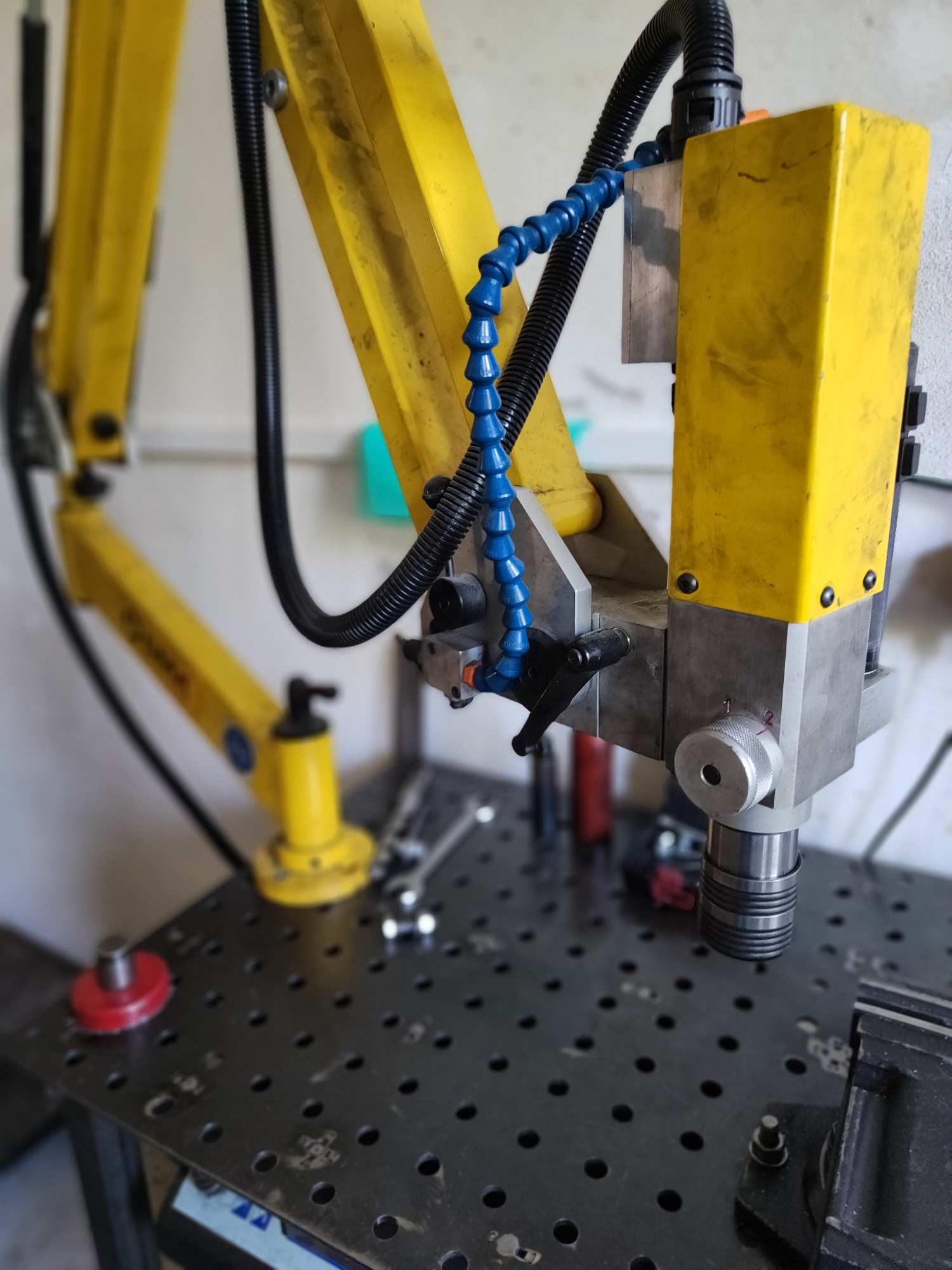

- Drilling:

- Maximum drilled diameter Ø 40 mm

- Speed control

- Cooling

- Automatic feed

- Threading:

- Electric threading machine for M3-M24 threads

- Two-speed transmission

- Multi-position head

- Electronic speed adjustment

- Automatic mode

- Riveting:

- Riveting screw and nut rivets M3-M12

- Riveting of blind rivets up to Ø 6.4 mm

- Stud Welding:

- CD welding of studs and similar elements

- Welding range Ø 2-8 mm

- Stud material – steel, stainless steel, aluminium

- Straightening of Parts and Workpieces:

- Straightening Presses: 10-30 t